Pipe Rack Fabrication

FABRICATION

- 8 COVERED BAYS FOR COMPLETION OF PARTS UP TO SIZE OF 192M Х 36M Х 21,9M (L X C X H)

- OVERHEAD CRANES, WITH 90 T UP TO 180 T LIFTING CAPACITY IN EACH BAY

PAINTING

- 3 DESIGNATED PAINTING WORKSHOPS AND INTERNAL CONTRACTOR FOR A TEMPORARY WORKSHOP

- OFFSHORE PAINTING SYSTEMS INCLUDING THERMAL SPRAYED ALUMINUM COATING(TSA)

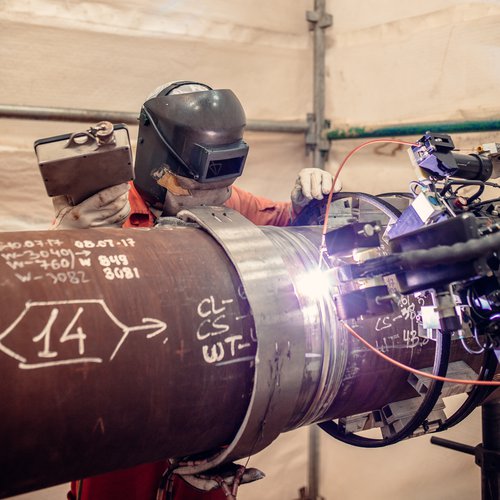

PIPE FABRICATION

- 2 PIPE FABRICATION WORKSHOP (1 EXOTIC + 1 CARBON STEEL PLATES)

- PROCEDURES: INCONEL COATED CARBON STEEL, SUPER DUPLEX STAINLESS STEEL, CUNIFER, LOW TEMPERATURE STAINLESS STEEL AND CHROME MOLYBDENUM

LOADING

- 25 CRAWLER AND MOBILE CRANES WITH LOADING CAPACITY UP TO 1350 T

- TOTAL LIFTING CAPACITY - MORE THAN 10,000 T

- 2 X 100 M CONCRETE COATED UNLOADING AREA (50T/M2)

- 28 M LONG 6 LOADING BAYS CONNECTED WITH STB 1 BARGE

SUCCESSES ACHIEVED

- DSG SUBSEA WATER INJECTION (WI) PROJECT (2012/13)

- WI (WATER INJECTION) MANIFOLD SPLITTERS

- # 1 (H02 & H03)

- # 2 (H05 & H06)

CONNECTOR PIPELINES

- H01, H02, H03, H04, H05, H06

- DSG SUBSEA WATER INJECTION (WI) PROJECT (2014/15)

- Water injection manifold splitters

- #2 (H07 & H08)

- Connector pipelines

- H07, H08

DSG subsea water injection (WI) project (WI) (2015/16)

- #3 (F05 & F07)

- #4 (G05 & G06)

- #5 (G07)

- Connector pipelines

- F05, F07, G05, G06, G07